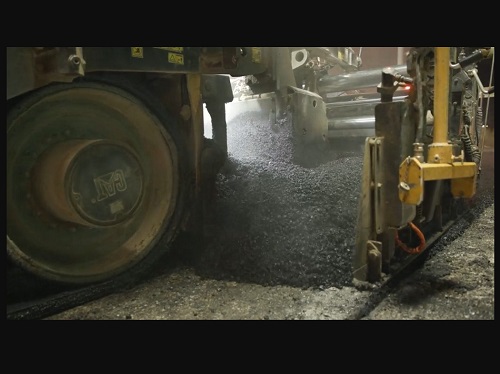

The Utah Department of Transportation is now using a new weather-resistant and durable asphalt mix that it developed to reduce road pavement costs, time, and repair needs.

[Above photo by Utah DOT]

The agency noted, with traditional asphalt mixes, crushed rock is mixed with binders that act as a glue. By contrast, Utah DOT’s new asphalt blend – called HiMod high density asphalt – uses a significantly higher ratio of polymer in the asphalt binder than traditional asphalt mixes. The thicker, stickier result is much stronger than previously possible, meaning less wear and tear on the roads, the agency said.

Utah DOT said it tested the new HiMod asphalt blend on I-80 in Wendover at the Port of Entry on the border of Utah and Nevada in June 2021. The test site was selected for its extremities: Temperatures regularly reaching the triple digits in the summer, single digits in the winter, and heavy truck traffic regularly decelerating and accelerating – all adding to pavement distress.

In the past, those stresses meant the area required regular pavement maintenance. However, over three years after laying down the HiMod mix, the test site is still holding strong, the agency said.

“We’re always looking at ways to extend the life of our roads and save taxpayer money,” said Howard Anderson, the Utah DOT asphalt engineer who headed up the development team for this new asphalt mix.

“Changing something as simple as the materials used in our asphalt mix can have a tremendous impact, with fewer potholes, and longer-lasting roads,” he said in a statement. “This new mixture defies everything I studied about asphalt in school. But what I was taught in school was based on binders of the past, before we had polymers. With stronger glue, it didn’t make sense to keep doing the same things we’ve always done with asphalt. I wanted to do something better.”

Utah DOT is using this new asphalt on several construction projects this summer, including the I-80 ramps near the Salt Lake City International Airport, on I-80 going up Parleys Canyon, and repaving the I-215 eastbound off ramp to State Street.

In addition to being durable, Utah DOT said this new blend cuts the paving process in half. With traditional asphalt mixes, crews often lay down the pavement in two thin layers, called “lifts.” This allows them to roll the pavement evenly throughout, compacting the asphalt and removing air pockets to make it more durable. This two-layer application means that crews must place one layer down, compact it, wait for it to set, test it, and add an adhesive coating before repeating the process with another layer.

By contrast, the new HiMod high density mix allows crews to do up to a single, six-inch lift without compromising compaction. Samples from the test site showed even compaction throughout, with much higher compaction rates than traditional asphalt mixes. This translates to stronger, more durable roads, with half the labor, Anderson noted.

He added that his team has not finished testing this new asphalt mix, for he wants to analyze it in even thicker lifts, as high as eight inches, and believes that that may be the key to creating “perpetual pavement.” And Anderson isn’t limiting his plans to highways.

“This mix sets up faster than concrete and is more durable than traditional asphalt, and we can use it on sidewalks, trails, you name it,” he explained. “Asphalt has stayed in its lane, so to speak, for decades, but it’s time for us to step it up and move beyond that. This mix opens so many opportunities for the asphalt industry as a whole.”

States

States

Louisiana Celebrates Completion of $30M Bridge Project

February 20, 2026 States

States