A recent Texas Department of Transportation blog post detailed how the agency is using three different types of robots to conduct a variety of infrastructure-related work.

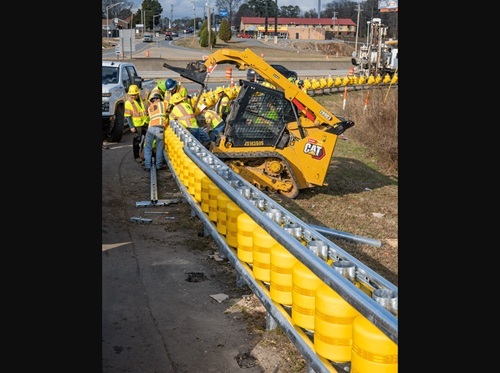

[Above photo by TxDOT]

First, there is the “TyBOT,” or rebar-tying robot, being used in the area around Odessa, TX. Next, there is “Spot,” a data-collection four-legged robot in use around Austin. Finally, there is “WALL-E,” the storm-drain inspection robot also being used in the Austin area.

These innovative machines are helping TxDOT be safer and more efficient in areas from construction to inspections, noted Matthew Bryant with TxDOT’s engineering services team, in the blog post.

“The idea of having tools like these within the department is truly to keep us as safe as possible,” he explained. “It is completely safety driven.”

The agency said the “WALL-E” inspection unit aims to protect workers from unknown hazards potentially lurking in storm-drains.

“There are unknown hazards sometimes that are in storm drains, like snakes, rats and debris, so we would send WALL-E in versus sending someone else in, being in danger, and getting hurt,” said John Gordon, TxDOT storm drain inspector, in the post.

Meanwhile, TxDOT has been using the TyBOT – developed by Advanced Construction Robotics – since May 2022; first on the SH 302 Highway Project in Winkler County in the Odessa area.

That project constructed two overpasses for the highway – one over the Texas-New Mexico Railroad and the other over SH 115 – to eliminate a four-way stop that caused traffic and safety issues.

“TyBOT makes it safer for workers,” said Saul Romero, director of construction for TxDOT in Odessa. “TyBOT allows one operator to stand upright and tie the rebar using a joystick.”

The machine can tie up to 1,100 rebar connections per hour; not only saving time but eliminating the physical wear and tear on the bodies of human workers, since tying rebar can be hard on knees, hands, and backs.

“It is back-breaking work to tie steel, literally,” Romero said. “It’s much better and faster to have just one worker controlling the TyBOT with a joystick while standing upright instead of a crew tying rebar manually.”

Spot – created by Boston Dynamics – is a semi-autonomous, agile robot that assists with routine inspection and data collection tasks. The unit can collect data for three dimensional models, inventory existing structures, account for existing assets, provide a clear picture of job site progress on an ongoing basis, and much more.

Spot can be outfitted with sensors to meet mission requirements, such as light detection and ranging sensors, noted TxDOT’s Bryant.

“Spot enables accurate, scalable and rapid data collection and a continuous flow of information between field and office,” he said. “It can be 100 percent automated or remotely operated depending on the application.”

[Editor’s note: The Alaska Department of Transportation & Public Facilities is using a similar four-legged unit developed by Boston Dynamics, named Aurora, to deter wildlife from entering runways and aircraft operation areas at Fairbanks International Airport.]

Once Spot surveys a specific area, it can routinely inspect or gather data automatically in that space on its own at programmed times. The unit can navigate terrain and maneuver around obstacles using 360-degree perception.

“If someone puts a box in its way or drives a bulldozer in front of it, it’ll walk around it,” Bryant said. “I can [also] train someone to use Spot and collect data in 15 minutes.”

He added that Spot can also balance heavy loads – close to 30 pounds – while rolling over uncertain terrain like loose gravel, grass, small puddles and curves. Spot can even handle stairs with steps up to 12 inches high and inclines up to 30 degrees, Bryant said.

“Spot keeps engineers and technicians out of harm’s way,” Bryant said. “Instead of putting on special gear and crawling into a drainage ditch or tunnel – which can contain snakes and other hazards – TxDOT employees can send Spot at no risk to themselves. We can also now collect data we’ve never had before. This will help accelerate our projects.”

States

States

RIDOT Wraps I-95 Providence Viaduct Northbound Project

January 30, 2026 States

States