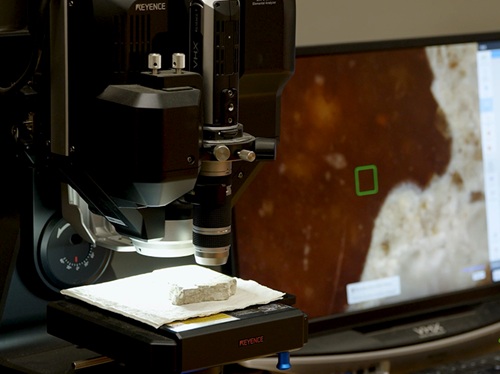

A recent Texas Department of Transportation blog post provided a behind-the-scenes look at the vital work performed by the agency’s Materials and Tests division laboratory to improve roadway quality and longevity.

[Above photo by TxDOT]

The agency explained that a lab team regularly performs a “petrographic analysis” as part of that roadway improvement effort – analyzing every roadway crack, every concrete mix, and every microscopic particle received from all over the state to check and ensure they meet strict safety standards.

“Petrographic analysis is essentially the use of microscopy, mineralogy, geology, and chemistry to look at different failures in the roads and do forensic analysis,” explained Maria Hruska, technical project manager at TxDOT’s Petrographic Lab, in the blog post.

She noted that this TxDOT lab relies on a variety of technologies, such as electron microscopes, to conduct its materials verification work – detecting damage that is invisible to the human eye.

“They are extremely useful in doing very, very fine, detailed work and helping us see stuff that even normal microscopes wouldn’t be able to see,” Hruska said. “Something that starts off really small, once it starts spreading, can cause some really large-scale cracking. And it’s actually known as ‘concrete cancer.’”

[Editor’s note: State departments of transportation are involved in a wide variety of materials research efforts aimed at improving infrastructure longevity and resiliency. For example, on an episode of the AASHTO re:source Q&A podcast in January, the Oklahoma Department of Transportation discussed how it is modernizing geotechnical processes and data management to make more informed engineering project decisions.AASHTO re:source is a technical service program offered by the American Association of State Highway and Transportation Officials.]

In a recent case, the lab received samples of concrete that failed critical strength tests. At first glance, it seemed like nothing was wrong with it, but the analysis revealed a surprise.

“We found out that actually air had been mixed into that concrete so much that it weakened it by about 30 percent,” she pointed out. “And that concrete actually had to be removed.”

In addition to advanced microscopes, the team also uses a Laser Induced Blast Spectroscopy or LIBS scope; technology also used by the U.S. space program.

“It’s actually the technology that’s used on the Mars rover,” Hruska said. “A laser will essentially hit the surface and do an elemental analysis.”

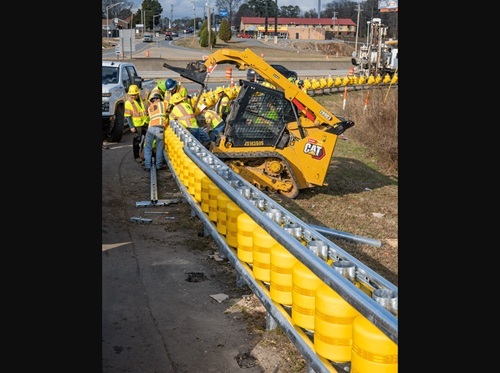

[In a separate TxDOT blog post, the agency described how potholes form and how its crews fix them – large and small alike – on roadways statewide.]

Still, while TxDOT’s Materials and Tests division works hard to improve road quality and safety, Hruska stressed that it takes a broader team effort of engineers, law enforcement, and motorists working together to prevent crashes and save lives.

“We put so much time and energy and effort into making sure these roadways are as safe as possible, but at the end of the day, you still have to drive like a Texan: kind, courteous, and safe,” Hruska said.

States

States

RIDOT Wraps I-95 Providence Viaduct Northbound Project

January 30, 2026 States

States