The latest episode of the AASHTO re:source podcast takes a deep dive into changes the group made to its proficiency sampling program or PSP process in 2023.

[Above image by AASHTO re:source]

AASHTO re:source – a division of the American Association of State Highway and Transportation Officials – provides services and tools through three major programs: the Laboratory Assessment Program or LAP, the PSP, and the AASHTO Accreditation Program. It launched this podcast series in September 2020.

The guest lineup for the group’s PSP process podcast included John Malusky, PSP director; Ryan LaQuay, laboratory and testing manager; and Joe Williams, senior quality analyst. They talked in detail about long-planned changes to AASHTO re:source’s Marshall and Hveem asphalt mixture proficiency sampling processes that occurred in 2023.

[Editor’s note: This article details how Francis Hveem – pronounced “veem” as the “h” is silent – played a pivotal role in changing aggregate testing and sampling methods in order to improve roadway surface quality and longevity.]

“This year we made the move to separate the Hveem samples by the method of compaction, Malusky explained on the podcast.

“Essentially the methods were combined or the methods of compaction were combined into one sample round. That doesn’t mean the data was all pulled together; we still separate everything by compaction. But … the data sheets, the instructions letter, the whole situation was very, very confusing. We would have essentially seven pages of instructions; each one [with] a slightly different mix design based off the amount of material that’s needed. That meant there was a more chances for errors and mistakes.”

As a result, AASHTO re:source decided to separate the three methods via its three compaction methods; ultimately running three separate sample test. “It didn’t really have too much of an effect on anything from a production standpoint; it really meant just labeling boxes and bags a little bit differently than in the past.”

The upshot of that change, however, is far simpler instruction sheets for AASHTO re:source client laboratories.

“This is one of the first years where we did not have any negative feedback on the instructions and clarity of them, so that is a huge thing,” Malusky pointed out. “It’s about continual improvement; we took feedback from all the participants and actually made a meaningful change to our processes.” To listen to the full podcast episode, click here.

AASHTO

AASHTO

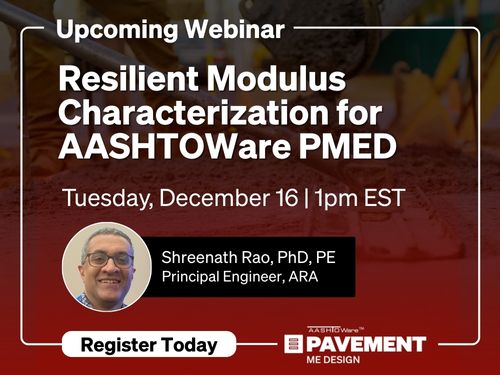

AASHTOWare Webinar: The Impact of ‘Resilient Modulus’

December 12, 2025 AASHTO

AASHTO