The latest episode of the AASHTO re:source Q&A podcast delves into the meticulous planning process behind the Hamburg Wheel Tracking samples; a groundbreaking addition to its Proficiency Sample Program or PSP.

[Above image by AASHTO]

AASHTO re:source is a technical service program offered by the American Association of State Highway and Transportation Officials that provides services and tools through three major programs: the Laboratory Assessment Program, the PSP, and the AASHTO Accreditation Program. Its mission is to collaborate with key stakeholders to provide services that ensure the integrity of the materials used to build the nation’s infrastructure.

The Hamburg Wheel Tracking test is one of the primary performance tests included in the Balanced Mix Design process to evaluate the rutting and stripping potential of an asphalt mixture.

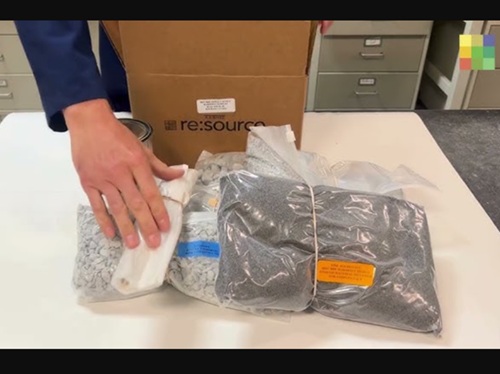

By providing the Hamburg Wheel Track proficiency sample, AASHTO re:source aims to reduce variability in test results, ensuring that all participating laboratories can achieve comparable and reliable outcomes.

With importance of collaboration and research in refining the program in mind, AASHTO re:source worked closely with plant producers, state department of transportation staff, and other industry experts to develop a feasible and effective methodology.

Pilot programs with several DOTs revealed issues such as confusion with sample reduction/splitting and variation during sample preparation and testing – challenges that underscore the importance of standardizing the process to achieve accurate and reliable results.

Ultimately, this Q&A podcast episode highlights the design and development of a plan relating to procedures and protocols for specimen preparation and the steps taken to overcome variation; ensuring the Hamburg Wheel Track sample meets industry standards and needs.

AASHTO

AASHTO

AASHTO Re:source Informational Webinar on January 6

January 2, 2026 AASHTO

AASHTO