The House of Representatives Committee on Transportation and Infrastructure held a hearing on January 17 to review the state of the U.S. transportation network and the nation’s ability to effectively and efficiently move goods and people via its multimodal connections.

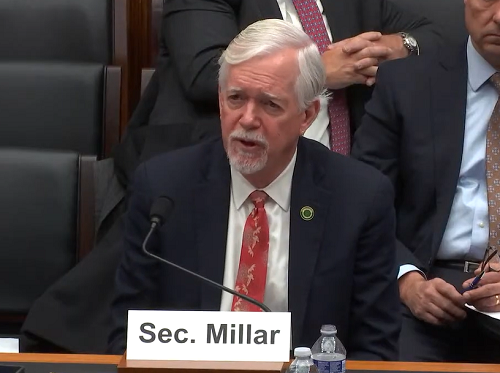

[Above photo by the House T&I Committee]

Roger Millar – secretary of the Washington State Department of Transportation and immediate past president of the American Association of State Highway and Transportation Officials – was one of four witnesses questioned during the hearing.

The other three were Stephen Edwards, CEO and executive director of the Virginia Port Authority; Jeffrey Tucker, CEO of Tucker Company Worldwide on behalf of the Transportation Intermediaries Association; and Lauren Benford, controller for the Reiman Corporation on behalf of Associated General Contractors of America.

Millar presented the state department of transportation view of the present and future challenges facing not only U.S. supply chains but its people-focused transport networks as well – especially from a safety perspective.

“For years, infrastructure investment did not keep pace with our needs. The impacts of a lack of adequate investment to preserve and enhance our systems for all users are readily apparent and will take time and hard work to overcome,” he explained in his testimony. “There is also the cost – both monetarily and in human suffering – which we all pay as a society when it comes to transportation funding and issues such as safety.”

Millar noted, for example, that the combined budgets of all state DOTs is nearly $200 billion a year – yet crashes cost the U.S. economy $1.4 trillion annually in economic and societal impacts. “Not having our system in a state of good repair costs another $142 billion a year,” he added. “[Traffic] congestion’s annual cost is $110 billion, with another $107 billion for greenhouse gas emissions.”

Millar also noted that state DOTs are also experiencing project cost escalation alongside workforce shortages, which is complicating efforts to maintain, reimagine, and rebuild the nation’s transportation system.

“The COVID-19 pandemic placed an unprecedented strain on the supply chain resulting in increased material costs – and material pricing volatility adds risks to projects,” he said. “This is especially challenging for our largest, most complex projects because we are asking contractors to estimate these costs years into the future. Consequently, it’s on these types of projects that we are seeing the largest cost increases.”

While state DOTs are generally not experiencing the same supply chain issues as they did during and immediately following the COVID-19 pandemic, other external pressures are still affecting project costs, Millar emphasized.

“These include market conditions exacerbated by strong, unprecedented competition among agencies for the same material and workforce pool,” he explained. “Workforce availability is a challenge for the entire transportation sector as we work together to deliver new projects and programs funded by the IIJA [Infrastructure Investment and Jobs Act] and state and local governments. This involves all phases of project work and quite simply the current near-term demand outweighs the supply.”

Millar pointed out that many government transportation agencies and private sector partners also are experiencing employee loss due to retirement and attrition; issues that exacerbate ongoing hiring challenges.

“Those challenges also affect schedule, ultimately affecting overall project costs,” he said. “State DOTs and contractors are ramping up to deliver the projects funded through IIJA but a massive increase in projects also requires a workforce increase, and we hope Congress will provide a robust and sustained level of funding as our federal partner so that everyone, especially our private sector partners, will invest to ramp up, keep up, and deliver on these vital projects.”

Top Stories

Top Stories

USDOT Makes $1.5B Worth of BUILD Grants Available

December 19, 2025 Top Stories

Top Stories